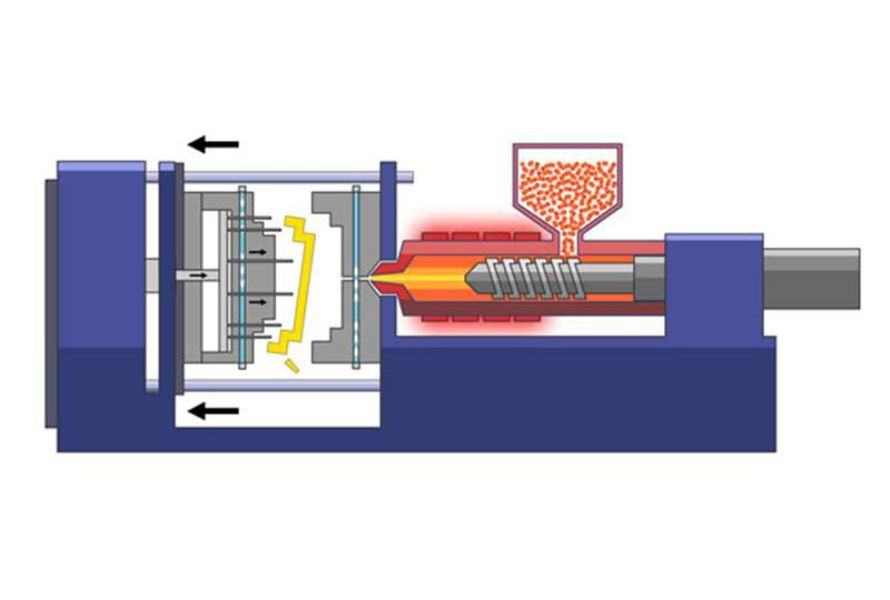

Ensuring Quality in Injection Molding with Synertek Plast Injection molding is a complex process where precision and expertise are crucial to producing high-quality plastic components. Even minor variations in temperature, pressure, or material consistency can lead to defects that affect the final product's performance and appearance. At Synertek Plast, we understand the challenges of maintaining consistency and quality in every injection-molded part. Our team is committed to providing comprehensive solutions that address these challenges, from the initial design phase to final production. Leveraging our advanced manufacturing capabilities, including state-of-the-art CNC machining, 3D CAD design, and rigorous quality control processes, we identify and mitigate potential issues before they escalate. By focusing on precision and customization, we ensure that your products meet the highest standards, free from common defects that can disrupt production and increase costs. Common Defects in Injection Molding and Remedies 1. Warping: - Cause: Uneven cooling or residual stresses in the part. - Remedy: Ensure uniform cooling, adjust cooling time, and optimize mold design to reduce internal stresses. 2. Sink Marks: - Cause: Insufficient cooling or excessive material in thick sections. - Remedy: Increase cooling time, reduce wall thickness, or adjust packing pressure. 3. Flash: - Cause: Excessive injection pressure, worn mold parts, or improper clamping. - Remedy:Decrease injection pressure, repair or replace worn mold parts, and ensure proper clamping force. 4. Short Shots: - Cause: Inadequate material flow or insufficient injection pressure. - Remedy: Increase injection pressure, raise melt temperature, or adjust gate size and placement. 5. Burn Marks: - Cause: Overheating of the material or trapped air in the mold. - Remedy: Lower the injection speed, ensure proper venting, and adjust mold temperature. 6. Bubbles and Voids: - Cause: Trapped air, excessive moisture, or incorrect pressure settings. - Remedy: Dry the material thoroughly, optimize injection pressure, and improve mold venting. How Synertek Plast Expertise Can Help At Synertek Plast, we specialize in high-precision mold manufacturing and injection molding, ensuring that every product meets the highest standards. Our team of experienced engineers uses advanced 3D CAD design, CNC machining, and mold flow analysis to predict and prevent common defects. By leveraging state-of-the-art equipment and a rigorous quality control process, we ensure consistent, defect-free production. Key Benefits of Synertek Expertise: - Advanced Tooling: Precision CNC machining and mold design ensure accurate and defect-free molds. - Quality Control: Continuous monitoring and testing during the molding process to detect and correct defects early. - Customized Solutions: Tailored injection molding solutions to meet specific material and product requirements. - Prototyping & Testing: Functional prototyping and mold trials to refine designs before full-scale production. With Synertek Plast, you can trust that your products will be produced to the highest quality, minimizing defects and ensuring smooth, efficient production. #InjectionMolding #PlasticMolding #MoldManufacturing #PrecisionMolding #CNCMachining #3DCADDesign #QualityControl #ProductDevelopment #SynertekPlast #ManufacturingSolutions #PlasticIndustry #MoldDesign #Prototyping #EngineeringPlastics.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.synertekplast.com/latest-update/ensuring-quality-in-injection-molding-with-synerte/25

Ensuring Quality in Injection Molding with Synerte...

2024-08-11T13:45:09

Ensuring Quality in Injection Molding with Synertek Plast Injection molding is a complex process where precision and expertise are crucial to producing high-quality plastic components. Even minor variations in temperature, pressure, or material consistency can lead to defects that affect the final product's performance and appearance. At Synertek Plast, we understand the challenges of maintaining consistency and quality in every injection-molded part. Our team is committed to providing comprehensive solutions that address these challenges, from the initial design phase to final production. Leveraging our advanced manufacturing capabilities, including state-of-the-art CNC machining, 3D CAD design, and rigorous quality control processes, we identify and mitigate potential issues before they escalate. By focusing on precision and customization, we ensure that your products meet the highest standards, free from common defects that can disrupt production and increase costs. Common Defects in Injection Molding and Remedies 1. Warping: - Cause: Uneven cooling or residual stresses in the part. - Remedy: Ensure uniform cooling, adjust cooling time, and optimize mold design to reduce internal stresses. 2. Sink Marks: - Cause: Insufficient cooling or excessive material in thick sections. - Remedy: Increase cooling time, reduce wall thickness, or adjust packing pressure. 3. Flash: - Cause: Excessive injection pressure, worn mold parts, or improper clamping. - Remedy:Decrease injection pressure, repair or replace worn mold parts, and ensure proper clamping force. 4. Short Shots: - Cause: Inadequate material flow or insufficient injection pressure. - Remedy: Increase injection pressure, raise melt temperature, or adjust gate size and placement. 5. Burn Marks: - Cause: Overheating of the material or trapped air in the mold. - Remedy: Lower the injection speed, ensure proper venting, and adjust mold temperature. 6. Bubbles and Voids: - Cause: Trapped air, excessive moisture, or incorrect pressure settings. - Remedy: Dry the material thoroughly, optimize injection pressure, and improve mold venting. How Synertek Plast Expertise Can Help At Synertek Plast, we specialize in high-precision mold manufacturing and injection molding, ensuring that every product meets the highest standards. Our team of experienced engineers uses advanced 3D CAD design, CNC machining, and mold flow analysis to predict and prevent common defects. By leveraging state-of-the-art equipment and a rigorous quality control process, we ensure consistent, defect-free production. Key Benefits of Synertek Expertise: - Advanced Tooling: Precision CNC machining and mold design ensure accurate and defect-free molds. - Quality Control: Continuous monitoring and testing during the molding process to detect and correct defects early. - Customized Solutions: Tailored injection molding solutions to meet specific material and product requirements. - Prototyping & Testing: Functional prototyping and mold trials to refine designs before full-scale production. With Synertek Plast, you can trust that your products will be produced to the highest quality, minimizing defects and ensuring smooth, efficient production. #InjectionMolding #PlasticMolding #MoldManufacturing #PrecisionMolding #CNCMachining #3DCADDesign #QualityControl #ProductDevelopment #SynertekPlast #ManufacturingSolutions #PlasticIndustry #MoldDesign #Prototyping #EngineeringPlastics.

2024-08-11T13:45:09

Keywords

- gate size

- Burn Marks

- Sink Marks

- Trapped air

- Short Shots

- mold trials

- mold design

- Key Benefits

- cooling time

- mold venting

- art equipment

- common defects

- wall thickness

- thick sections

- Uneven cooling

- proper venting

- uniform cooling

- injection speed

- highest quality

- complex process

- molding process

- worn mold parts

- melt temperature

- mold temperature

- potential issues

- minor variations

- final production

- Advanced Tooling

- specific material

- internal stresses

- residual stresses

- highest standards

- defect-free molds

- improper clamping

- art CNC machining

- Synertek Expertise

- excessive material

- excessive moisture

- mold flow analysis

- material consistency

- product requirements

- Customized Solutions

- Insufficient cooling

- initial design phase

- injection-molded part

- Continuous monitoring

- experienced engineers

- full-scale production

- proper clamping force

- Functional prototyping

- advanced 3D CAD design

- comprehensive solutions

- Precision CNC machining

- Synertek Plast Expertise

- Inadequate material flow

- injection molding solutions

- incorrect pressure settings

- Excessive injection pressure

- smooth, efficient production

- insufficient injection pressure

- high-quality plastic components

- high-precision mold manufacturing

- QualityControl #ProductDevelopment

- consistent, defect-free production

- rigorous quality control processes

- advanced manufacturing capabilities

- SynertekPlast #ManufacturingSolutions

Submit Your Enquiry