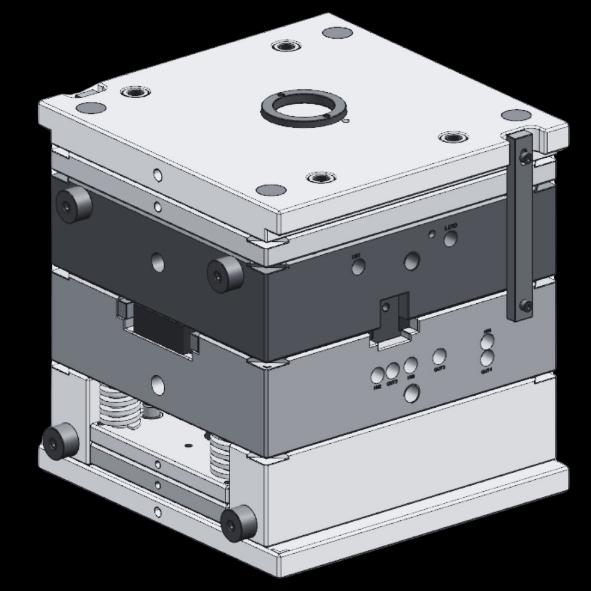

Injection molding mold design and making at Synertek Plast Vadodara. * An injection mold is an exterior template for a product. * Liquid plastic is injected into the mold and flows through the cavity to form the final product shape. * The process starts when the machine injects liquid plastic into the mold through a sprue, which is like a water pipe. * The plastic travels through a runner until it reaches the mold cavity, which is shaped exactly like the desired product. * After the plastic is solidified, the two parts of the mold open up and integrated ejector pins push into the mold cavity to remove the product. * Finally, the pins return to the original position and the mold is ready for its next shot. * The process of creating a mold starts with a 3D cad models that includes all basic mold making information, such as mold size, gating way, parting line, ejection way, cavities layout, mechanical design, and required accessories. * The 3D design is tested and optimized until it's ready for CNC machining. * During the initial machining process, a rough shape is carved out of a solid block of steel or aluminum through milling, drilling, and turning. * Next, precision machining finalizes the ultimate shape. * The mold is then assembled and is ready for its first trial run of injection molding. * There are many different types of molds that fulfill different production requirements. * Most molds are made from either steel or aluminum. * Steel molds are the most durable and can reliably repeat up to millions of shots, but they are also more expensive. * Aluminum molds are more affordable and faster to make, but they also have a shorter lifespan. * multi cavity molds are capable of producing products that consist of multiple parts or even materials. * These more advanced molds help cut assembly costs and overall production time. * There is no single perfect mold, but it needs to be tailored to the product's shape and function, desired output size, and speed. * An injection molding partner can help you make the right choice. for more details contact For more information or to discuss your specific needs, please contact us at: -Email: synertekplast@gmail.com, sales@synertekplast.com -Phone: 7984595573 (India) Keywords #Plasticmolding #twowheelerautocomponents #engineeringplastics #injectionmolds #toolsteels #highprecisionmolds #functionalprototypes #3Dprintedprototypes #productdesign #3Dmodeling #injectionmoldsGujarat #plasticcomponent #injectionmolding #MoldManufacturing

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.synertekplast.com/latest-update/injection-molding-mold-design-and-making-at-synert/17

Injection molding mold design and making at Synert...

2024-07-29T10:40:17

Injection molding mold design and making at Synertek Plast Vadodara. * An injection mold is an exterior template for a product. * Liquid plastic is injected into the mold and flows through the cavity to form the final product shape. * The process starts when the machine injects liquid plastic into the mold through a sprue, which is like a water pipe. * The plastic travels through a runner until it reaches the mold cavity, which is shaped exactly like the desired product. * After the plastic is solidified, the two parts of the mold open up and integrated ejector pins push into the mold cavity to remove the product. * Finally, the pins return to the original position and the mold is ready for its next shot. * The process of creating a mold starts with a 3D cad models that includes all basic mold making information, such as mold size, gating way, parting line, ejection way, cavities layout, mechanical design, and required accessories. * The 3D design is tested and optimized until it's ready for CNC machining. * During the initial machining process, a rough shape is carved out of a solid block of steel or aluminum through milling, drilling, and turning. * Next, precision machining finalizes the ultimate shape. * The mold is then assembled and is ready for its first trial run of injection molding. * There are many different types of molds that fulfill different production requirements. * Most molds are made from either steel or aluminum. * Steel molds are the most durable and can reliably repeat up to millions of shots, but they are also more expensive. * Aluminum molds are more affordable and faster to make, but they also have a shorter lifespan. * multi cavity molds are capable of producing products that consist of multiple parts or even materials. * These more advanced molds help cut assembly costs and overall production time. * There is no single perfect mold, but it needs to be tailored to the product's shape and function, desired output size, and speed. * An injection molding partner can help you make the right choice. for more details contact For more information or to discuss your specific needs, please contact us at: -Email: synertekplast@gmail.com, sales@synertekplast.com -Phone: 7984595573 (India) Keywords #Plasticmolding #twowheelerautocomponents #engineeringplastics #injectionmolds #toolsteels #highprecisionmolds #functionalprototypes #3Dprintedprototypes #productdesign #3Dmodeling #injectionmoldsGujarat #plasticcomponent #injectionmolding #MoldManufacturing

2024-07-29T10:40:17

Keywords

- mold size

- next shot

- two parts

- 3D design

- Most molds

- gating way

- water pipe

- Steel molds

- mold cavity

- mold design

- output size

- solid block

- rough shape

- ejector pins

- right choice

- ejection way

- parting line

- CNC machining

- 3D cad models

- Aluminum molds

- Liquid plastic

- specific needs

- assembly costs

- advanced molds

- multiple parts

- ultimate shape

- desired product

- cavities layout

- first trial run

- shorter lifespan

- mechanical design

- original position

- exterior template

- multi cavity molds

- precision machining

- final product shape

- single perfect mold

- required accessories

- many different types

- overall production time

- Synertek Plast Vadodara

- initial machining process

- injection molding partner

- basic mold making information

- different production requirements

Submit Your Enquiry