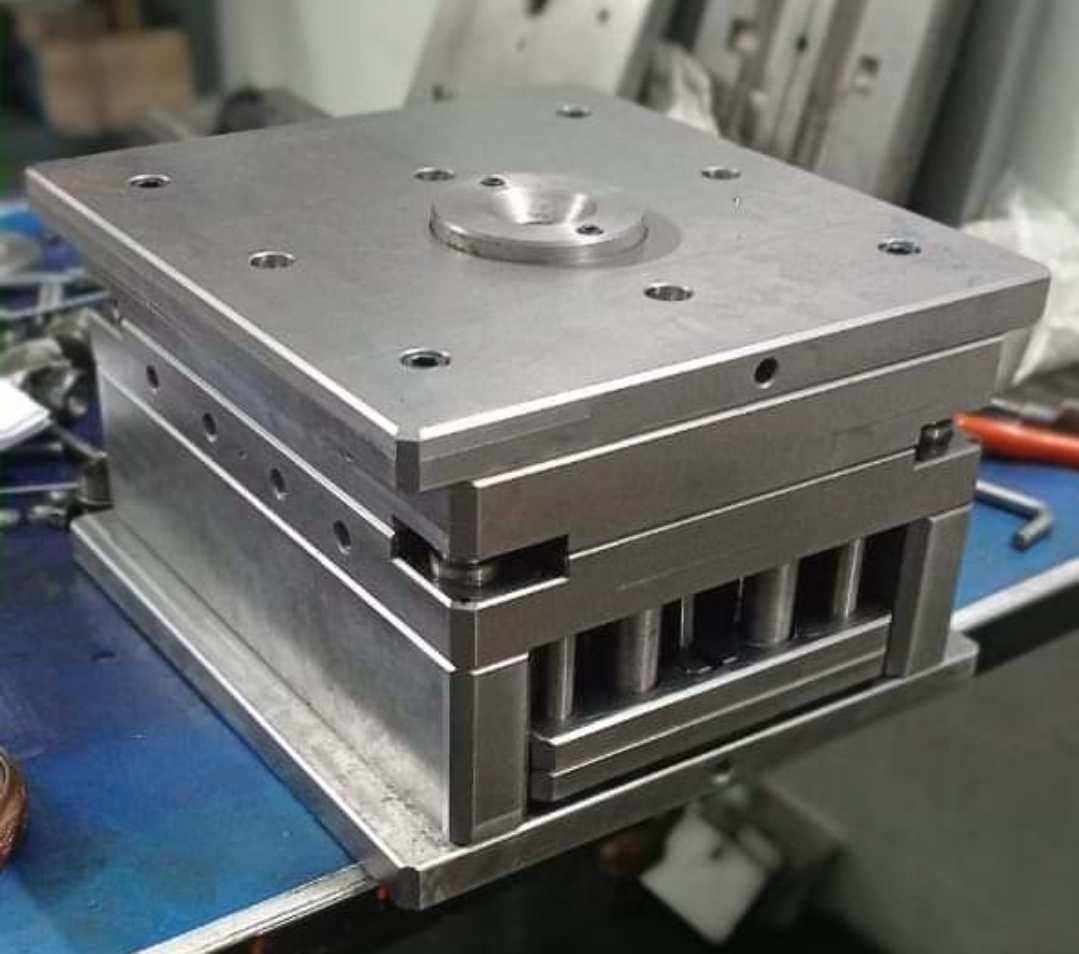

Mold Making for Plastic Injection Molds: A Comprehensive Overview 1. Design Process: The mold-making process begins with a detailed design phase. Engineers and designers work closely with clients to understand the product requirements, including shape, size, material, and functionality. Using advanced 3D CAD software, a detailed digital model of the mold is created. This model serves as the blueprint for the entire manufacturing process, allowing engineers to simulate the injection process, identify potential issues, and optimize the design for efficiency and quality. 2. Material Selection for Molds: The choice of materials for the mold is crucial for ensuring durability, precision, and longevity. Commonly used materials include tool steels such as P20, H13, and S7, each offering different characteristics like hardness, toughness, and wear resistance. The selection depends on the type of plastic being molded, the expected production volume, and the complexity of the mold design. For high-precision applications, materials with superior hardness and heat resistance are preferred to maintain tight tolerances over long production runs. 3. Mold Design: Once the material is selected, the mold design is refined. This involves creating the mold’s cavity and core, which are the negative and positive shapes of the final product, respectively. The design also includes the gating system, which directs the flow of molten plastic into the mold, and the cooling channels, which help to rapidly cool and solidify the plastic. Engineers must carefully consider factors like shrinkage, ejection mechanisms, and parting lines to ensure that the mold functions correctly and produces high-quality parts. 4. Machining Processes: The machining process is where the digital design is transformed into a physical mold. This involves several precision machining techniques: - CNC Milling: CNC (Computer Numerical Control) milling machines are used to create the main features of the mold. The CNC machine follows the 3D CAD model to accurately cut and shape the mold materials with high precision. - EDM (Electrical Discharge Machining):For creating intricate details, deep cavities, and sharp corners that CNC milling cannot achieve, EDM is employed. This process uses electrical discharges (sparks) to erode the material, allowing for high precision and detail. - Grinding and Polishing: After the initial machining, grinding and polishing are performed to achieve the required surface finish and tolerance. This step is critical for ensuring that the molded parts are smooth and free from defects. 5. Precision Assembly: Following the machining process, the mold components are carefully assembled. This involves fitting the core and cavity together, installing the gating system, and aligning the cooling channels. Precision is key during assembly, as any misalignment can lead to defects in the final product. Engineers also install the ejection system, which will later remove the molded parts from the mold. 6. Troubleshooting and Testing: Once the mold is assembled, it undergoes rigorous testing to ensure that it functions as intended. This stage includes trial runs where molten plastic is injected into the mold to produce sample parts. Engineers closely inspect these parts for any defects such as warping, incomplete filling, or surface imperfections. If any issues are identified, they troubleshoot by adjusting the mold design, refining the machining process, or tweaking the injection parameters. This iterative process continues until the mold produces parts that meet the desired quality standards. 7. Finalization and Maintenance: After successful testing, the mold is finalized for production. Engineers document the mold’s specifications, maintenance requirements, and operational guidelines. Regular maintenance is critical to extend the mold’s life, which includes cleaning, re-polishing surfaces, and checking for wear and tear. Our Expertise in Mold Making Across India At Synertek Plast, we specialize in high-precision mold making for plastic injection molds, serving clients across India. Our advanced facilities in Vadodara, Gujarat, and expertise in the latest CNC machining, EDM, and mold design technologies ensure that we deliver top-quality molds that meet the stringent demands of various industries. We provide comprehensive plastic mold making services in major cities including Delhi, Mumbai, Bangalore, Chennai, Hyderabad, Pune, Ahmedabad, Kolkata, Surat, and Jaipur. Whether you need molds for consumer goods, automotive components, or industrial applications, we have the experience and capacity to meet your needs. Our services include: - 3D CAD Design and Simulation: Ensuring optimal mold design with minimal defects. - CNC Milling and EDM:Precision machining for complex and high-tolerance mold components. - Grinding, Polishing, and Surface Finishing: Achieving the perfect finish for your products. - Prototyping and Testin

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.synertekplast.com/latest-update/mold-making-for-plastic-injection-molds-a-compreh/23

Mold Making for Plastic Injection Molds: A Compreh...

2024-08-08T10:59:33

Mold Making for Plastic Injection Molds: A Comprehensive Overview 1. Design Process: The mold-making process begins with a detailed design phase. Engineers and designers work closely with clients to understand the product requirements, including shape, size, material, and functionality. Using advanced 3D CAD software, a detailed digital model of the mold is created. This model serves as the blueprint for the entire manufacturing process, allowing engineers to simulate the injection process, identify potential issues, and optimize the design for efficiency and quality. 2. Material Selection for Molds: The choice of materials for the mold is crucial for ensuring durability, precision, and longevity. Commonly used materials include tool steels such as P20, H13, and S7, each offering different characteristics like hardness, toughness, and wear resistance. The selection depends on the type of plastic being molded, the expected production volume, and the complexity of the mold design. For high-precision applications, materials with superior hardness and heat resistance are preferred to maintain tight tolerances over long production runs. 3. Mold Design: Once the material is selected, the mold design is refined. This involves creating the mold’s cavity and core, which are the negative and positive shapes of the final product, respectively. The design also includes the gating system, which directs the flow of molten plastic into the mold, and the cooling channels, which help to rapidly cool and solidify the plastic. Engineers must carefully consider factors like shrinkage, ejection mechanisms, and parting lines to ensure that the mold functions correctly and produces high-quality parts. 4. Machining Processes: The machining process is where the digital design is transformed into a physical mold. This involves several precision machining techniques: - CNC Milling: CNC (Computer Numerical Control) milling machines are used to create the main features of the mold. The CNC machine follows the 3D CAD model to accurately cut and shape the mold materials with high precision. - EDM (Electrical Discharge Machining):For creating intricate details, deep cavities, and sharp corners that CNC milling cannot achieve, EDM is employed. This process uses electrical discharges (sparks) to erode the material, allowing for high precision and detail. - Grinding and Polishing: After the initial machining, grinding and polishing are performed to achieve the required surface finish and tolerance. This step is critical for ensuring that the molded parts are smooth and free from defects. 5. Precision Assembly: Following the machining process, the mold components are carefully assembled. This involves fitting the core and cavity together, installing the gating system, and aligning the cooling channels. Precision is key during assembly, as any misalignment can lead to defects in the final product. Engineers also install the ejection system, which will later remove the molded parts from the mold. 6. Troubleshooting and Testing: Once the mold is assembled, it undergoes rigorous testing to ensure that it functions as intended. This stage includes trial runs where molten plastic is injected into the mold to produce sample parts. Engineers closely inspect these parts for any defects such as warping, incomplete filling, or surface imperfections. If any issues are identified, they troubleshoot by adjusting the mold design, refining the machining process, or tweaking the injection parameters. This iterative process continues until the mold produces parts that meet the desired quality standards. 7. Finalization and Maintenance: After successful testing, the mold is finalized for production. Engineers document the mold’s specifications, maintenance requirements, and operational guidelines. Regular maintenance is critical to extend the mold’s life, which includes cleaning, re-polishing surfaces, and checking for wear and tear. Our Expertise in Mold Making Across India At Synertek Plast, we specialize in high-precision mold making for plastic injection molds, serving clients across India. Our advanced facilities in Vadodara, Gujarat, and expertise in the latest CNC machining, EDM, and mold design technologies ensure that we deliver top-quality molds that meet the stringent demands of various industries. We provide comprehensive plastic mold making services in major cities including Delhi, Mumbai, Bangalore, Chennai, Hyderabad, Pune, Ahmedabad, Kolkata, Surat, and Jaipur. Whether you need molds for consumer goods, automotive components, or industrial applications, we have the experience and capacity to meet your needs. Our services include: - 3D CAD Design and Simulation: Ensuring optimal mold design with minimal defects. - CNC Milling and EDM:Precision machining for complex and high-tolerance mold components. - Grinding, Polishing, and Surface Finishing: Achieving the perfect finish for your products. - Prototyping and Testin

2024-08-08T10:59:33

Keywords

- trial runs

- CNC machine

- tool steels

- CNC Milling

- molded parts

- sample parts

- major cities

- 3D CAD model

- physical mold

- sharp corners

- deep cavities

- main features

- parting lines

- gating system

- final product

- 3D CAD Design

- mold materials

- perfect finish

- consumer goods

- Synertek Plast

- surface finish

- high precision

- molten plastic

- digital design

- minimal defects

- wear resistance

- ejection system

- positive shapes

- heat resistance

- potential issues

- rigorous testing

- cooling channels

- tight tolerances

- quality standards

- superior hardness

- stringent demands

- top-quality molds

- iterative process

- intricate details

- production volume

- 1. Design Process

- initial machining

- injection process

- Material Selection

- polishing surfaces

- Precision Assembly

- high-quality parts

- successful testing

- various industries

- incomplete filling

- Regular maintenance

- ejection mechanisms

- mold-making process

- Machining Processes

- advanced facilities

- optimal mold design

- product requirements

- injection parameters

- latest CNC machining

- long production runs

- surface imperfections

- automotive components

- electrical discharges

- detailed design phase

- operational guidelines

- Comprehensive Overview

- detailed digital model

- industrial applications

- Plastic Injection Molds

- maintenance requirements

- mold design technologies

- advanced 3D CAD software

- different characteristics

- high-precision mold making

- high-precision applications

- entire manufacturing process

- high-tolerance mold components

- Electrical Discharge Machining

- several precision machining techniques

- comprehensive plastic mold making services

- Computer Numerical Control) milling machines

Submit Your Enquiry