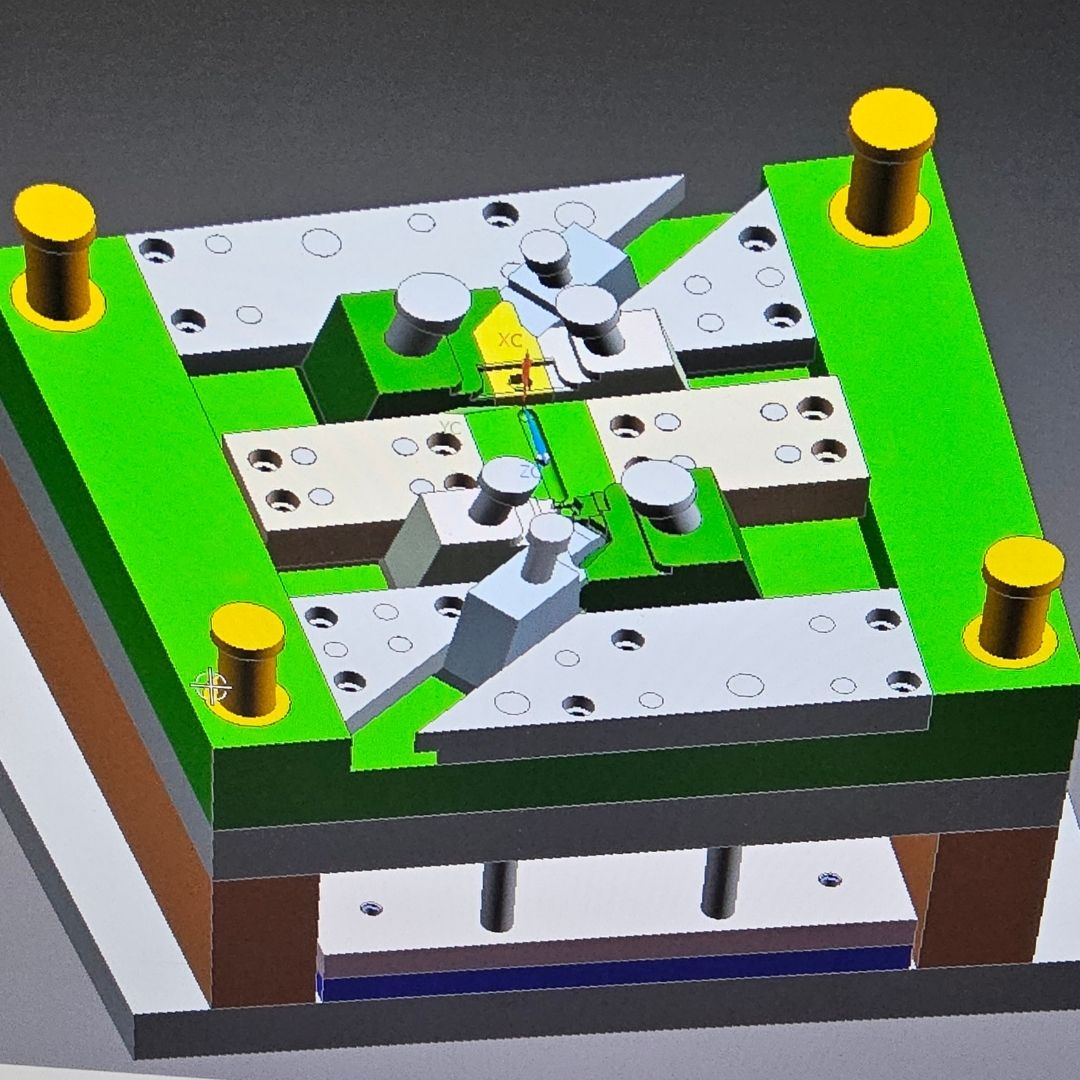

Mold Manufacturing Process at Synertek Plast 1. Requirement Analysis: Initial consultation with the client to understand the #productdesign, #materialselection, and functional requirements. Technical analysis and feasibility study for #molddesign and #manufacturing based on production volumes and material properties. 2. Design and Prototyping: #3DCADModeling: Synertek designs detailed #3Dmodels of the mold using CAD software to ensure accurate representation of the final product. #Prototyping: Functional prototypes are created using #3Dprinting or other #rapidprototyping methods for client approval and design validation. 3. Mold Design: The design team focuses on factors like #partinglines, cavity layout, #coolingchannels, and #ejectionsystems to ensure efficient production. Mold design also considers #materialflow, #shrinkage, and #cycletime for optimized performance. 4. CNC Machining and Spark EDM: The mold components are machined using #CNCmachining equipment to achieve precise dimensions and tolerances. Complex geometries and fine details are achieved using #SparkEDM for intricate cavity formation. 5. Mold Assembly and Testing: Components like #guidepillars, bushes, and plates are assembled with precision to ensure proper alignment and durability. Molds undergo thorough testing, including #moldtrials, to ensure they meet client specifications. 6. Polishing, Etching, and Finishing: The final stage involves #polishing to ensure smooth surfaces, and #etching if required, for texturing or specific surface finishes. Dos and Don'ts of Material Selection in Mold Manufacturing Dos: 1. Consider the Application: Always choose #moldmaterials based on the final product’s #mechanicalproperties and #thermalproperties. For #hightemperature applications, opt for #heatresistantsteels. For #highwear parts, choose durable, #abrasionresistant materials. 2. Assess Production Volume: Use high-quality, durable #moldmaterials for #highvolumeproduction to avoid premature wear. For #shortrunproduction, cost-effective materials like #aluminum may be considered. 3. Evaluate Plastic Material Properties: Select #moldsteel that is compatible with the plastic being injected, considering factors like: #meltingtemperature. abrasiveness of fillers (e.g., #glassfiber in nylon). 4. Ensure Corrosion Resistance: When molding #corrosiveplastics (like PVC), use #corrosionresistantsteel to avoid damage over time. 5. Use Heat Treatment: #Heattreat the mold material for strength and #wearresistance, especially for #highvolumemanufacturing. Don’ts: 1. Don’t Overlook Cooling: Poor material choice for #coolingchannels can lead to inefficient heat dissipation, affecting cycle time and part quality. 2. Avoid Inferior Steels: Low-quality or untreated steel will wear out quickly, resulting in high maintenance costs and frequent #moldrepairs. 3. Don’t Ignore Mold Material Compatibility with Injection Machine: Incompatible mold materials can cause issues like #flashing, #partdefects, or excessive wear on the machine. How Synertek Helps in Mold Development for Various Customer Segments 1. Consumer Goods: Synertek develops #highprecisionmolds for #plasticcomponents in #householditems, leveraging its #expertise in material selection for everyday use products. Offers #costeffectivesolutions for #highvolumeproduction with molds designed for #longevity and #repeatability. 2. Automotive Industry: Molds for #twowheeler and #automotivecomponents are made using #engineeringplastics like #PA6GF15 (glass-filled nylon), which require strong and #heatresistantmoldmaterials. Synertek ensures #tighttolerances and #durability to withstand the stresses of high-performance parts production. 3. Medical and Healthcare: Synertek ensures mold materials and designs are compatible with #hygienicstandards, offering #corrosionresistant and easy-to-clean molds for #medicalgradeplastics. 4. Packaging and Industrial Segments: Develops molds for #highspeedproduction and #consistentquality, catering to industries requiring #precise and #lightweightpackaging solutions. Expertise in designing molds that minimize #cycletimes and reduce #waste in production. 5. Small to Mid-Sized Enterprises: Synertek provides flexible mold development services for #startups and #SMEs, ensuring that mold designs can scale up with production demands. By providing customized solutions tailored to each #customersegment, Synertek ensures optimal #moldperformance, #longevity, and #costefficiency, guiding clients through #materialselection and ensuring the right choice for their applications.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Mold Manufacturing Process at Synertek Plast 1...

2024-10-14T12:05:46

Mold Manufacturing Process at Synertek Plast 1. Requirement Analysis: Initial consultation with the client to understand the #productdesign, #materialselection, and functional requirements. Technical analysis and feasibility study for #molddesign and #manufacturing based on production volumes and material properties. 2. Design and Prototyping: #3DCADModeling: Synertek designs detailed #3Dmodels of the mold using CAD software to ensure accurate representation of the final product. #Prototyping: Functional prototypes are created using #3Dprinting or other #rapidprototyping methods for client approval and design validation. 3. Mold Design: The design team focuses on factors like #partinglines, cavity layout, #coolingchannels, and #ejectionsystems to ensure efficient production. Mold design also considers #materialflow, #shrinkage, and #cycletime for optimized performance. 4. CNC Machining and Spark EDM: The mold components are machined using #CNCmachining equipment to achieve precise dimensions and tolerances. Complex geometries and fine details are achieved using #SparkEDM for intricate cavity formation. 5. Mold Assembly and Testing: Components like #guidepillars, bushes, and plates are assembled with precision to ensure proper alignment and durability. Molds undergo thorough testing, including #moldtrials, to ensure they meet client specifications. 6. Polishing, Etching, and Finishing: The final stage involves #polishing to ensure smooth surfaces, and #etching if required, for texturing or specific surface finishes. Dos and Don'ts of Material Selection in Mold Manufacturing Dos: 1. Consider the Application: Always choose #moldmaterials based on the final product’s #mechanicalproperties and #thermalproperties. For #hightemperature applications, opt for #heatresistantsteels. For #highwear parts, choose durable, #abrasionresistant materials. 2. Assess Production Volume: Use high-quality, durable #moldmaterials for #highvolumeproduction to avoid premature wear. For #shortrunproduction, cost-effective materials like #aluminum may be considered. 3. Evaluate Plastic Material Properties: Select #moldsteel that is compatible with the plastic being injected, considering factors like: #meltingtemperature. abrasiveness of fillers (e.g., #glassfiber in nylon). 4. Ensure Corrosion Resistance: When molding #corrosiveplastics (like PVC), use #corrosionresistantsteel to avoid damage over time. 5. Use Heat Treatment: #Heattreat the mold material for strength and #wearresistance, especially for #highvolumemanufacturing. Don’ts: 1. Don’t Overlook Cooling: Poor material choice for #coolingchannels can lead to inefficient heat dissipation, affecting cycle time and part quality. 2. Avoid Inferior Steels: Low-quality or untreated steel will wear out quickly, resulting in high maintenance costs and frequent #moldrepairs. 3. Don’t Ignore Mold Material Compatibility with Injection Machine: Incompatible mold materials can cause issues like #flashing, #partdefects, or excessive wear on the machine. How Synertek Helps in Mold Development for Various Customer Segments 1. Consumer Goods: Synertek develops #highprecisionmolds for #plasticcomponents in #householditems, leveraging its #expertise in material selection for everyday use products. Offers #costeffectivesolutions for #highvolumeproduction with molds designed for #longevity and #repeatability. 2. Automotive Industry: Molds for #twowheeler and #automotivecomponents are made using #engineeringplastics like #PA6GF15 (glass-filled nylon), which require strong and #heatresistantmoldmaterials. Synertek ensures #tighttolerances and #durability to withstand the stresses of high-performance parts production. 3. Medical and Healthcare: Synertek ensures mold materials and designs are compatible with #hygienicstandards, offering #corrosionresistant and easy-to-clean molds for #medicalgradeplastics. 4. Packaging and Industrial Segments: Develops molds for #highspeedproduction and #consistentquality, catering to industries requiring #precise and #lightweightpackaging solutions. Expertise in designing molds that minimize #cycletimes and reduce #waste in production. 5. Small to Mid-Sized Enterprises: Synertek provides flexible mold development services for #startups and #SMEs, ensuring that mold designs can scale up with production demands. By providing customized solutions tailored to each #customersegment, Synertek ensures optimal #moldperformance, #longevity, and #costefficiency, guiding clients through #materialselection and ensuring the right choice for their applications.

2024-10-14T12:05:46

Keywords

- Small to

- Spark EDM

- cycle time

- design team

- final stage

- Mold Design

- part quality

- fine details

- CAD software

- right choice

- CNC Machining

- final product

- Mold Assembly

- cavity layout

- Synertek Plast

- Consumer Goods

- excessive wear

- premature wear

- Heat Treatment

- highwear parts

- client approval

- mold components

- untreated steel

- Inferior Steels

- smooth surfaces

- Synertek designs

- thorough testing

- proper alignment

- Injection Machine

- design validation

- feasibility study

- glass-filled nylon

- precise dimensions

- production demands

- Complex geometries

- production volumes

- Technical analysis

- Material Selection

- Automotive Industry

- Industrial Segments

- customized solutions

- Corrosion Resistance

- efficient production

- Initial consultation

- Poor material choice

- client specifications

- Mid-Sized Enterprises

- frequent #moldrepairs

- optimized performance

- Functional prototypes

- everyday use products

- high maintenance costs

- accurate representation

- functional requirements

- 1. Requirement Analysis

- optimal #moldperformance

- cost-effective materials

- Various Customer Segments

- specific surface finishes

- Mold Manufacturing Process

- intricate cavity formation

- Plastic Material Properties

- Incompatible mold materials

- Mold Material Compatibility

- inefficient heat dissipation

- lightweightpackaging solutions

- other #rapidprototyping methods

- high-performance parts production

- flexible mold development services

- high-quality, durable #moldmaterials

- durable, #abrasionresistant materials

Submit Your Enquiry